Swift // FR our Free Ride wing foil board

Move your wing foiling to the next level on a Swift // Free Ride wing foil board...

SWIFT // FR

Introducing the Swift // FR- our free ride board that does it all.

Designed to fill the gap between our ML range and a more traditional shape.

We wanted to keep as much of the light wind performance gained by the ML as possible while providing a more compact outline, with improved responsiveness.

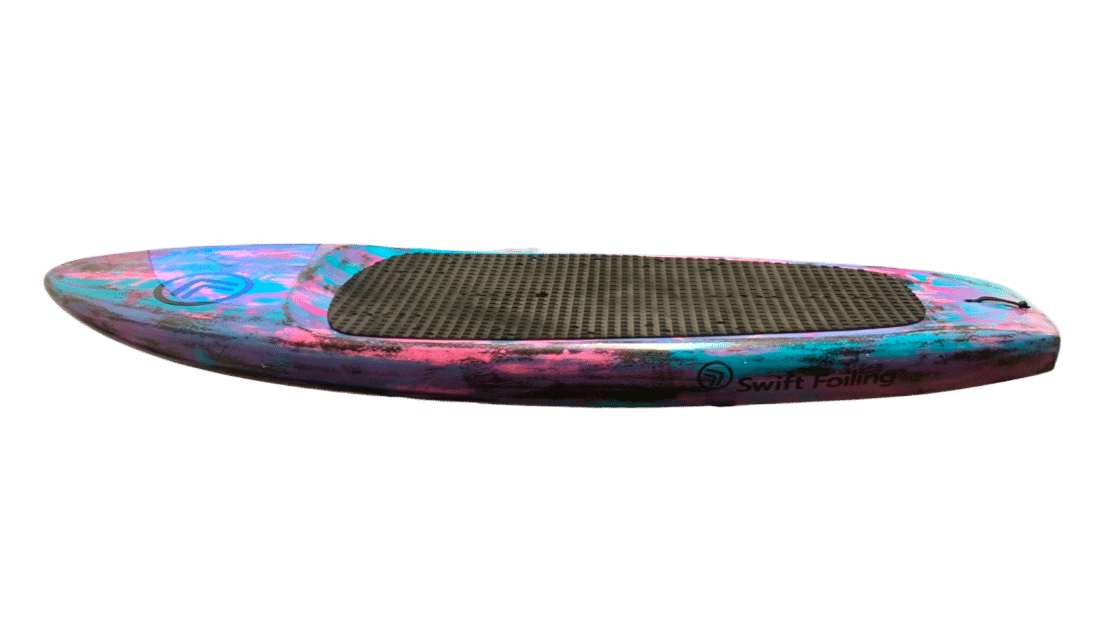

The narrow outline and optimized bottom shape provide excellent light wind performance, while added tail rocker, reduced length (compared to the ML) and a lightweight full carbon construction means it’s at home ripping turns and getting airborne. By dropping the deck we have decreased the distance between you and your foil providing you with a more responsive snappier ride.

What does all this mean? The Swift // FR is our free ride board that is sure to get you having more fun on the water!

Light weight and strong

A full carbon epoxy construction provides a stiff, lightweight and super rigid platform. This creates a responsive wing foil board which gives you that connected feeling whilst riding.

Evolving shape

Taking the best bits from the ML and NG we have created a wing foil board that does it all. With a gradual tail rocker and narrow outline it has excellent light wind performance whilst being able to rip turns and cut aggressive carves down faces.

Quick release design

The FR wing foil board is designed to get up and go. Easy to pump and quick to break from the water to give you the best ride.

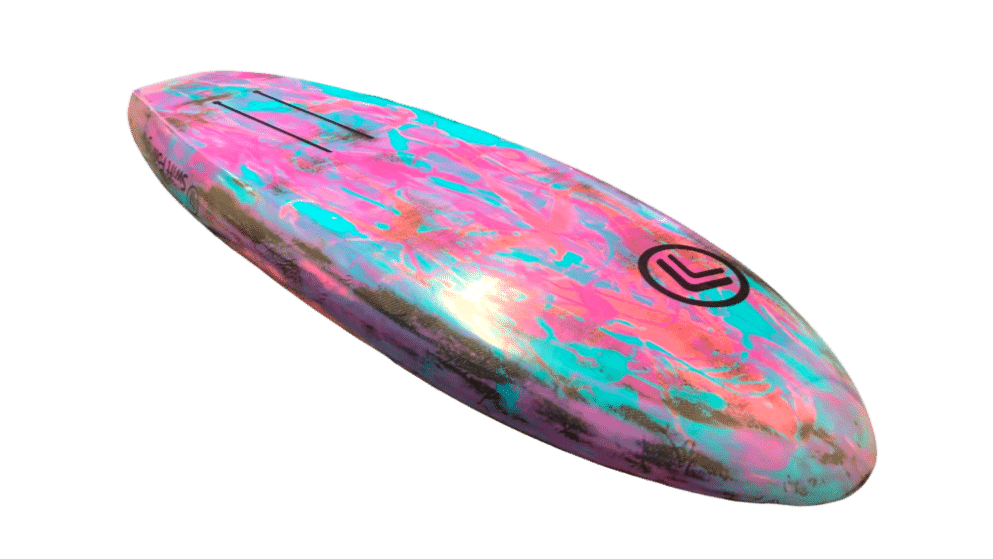

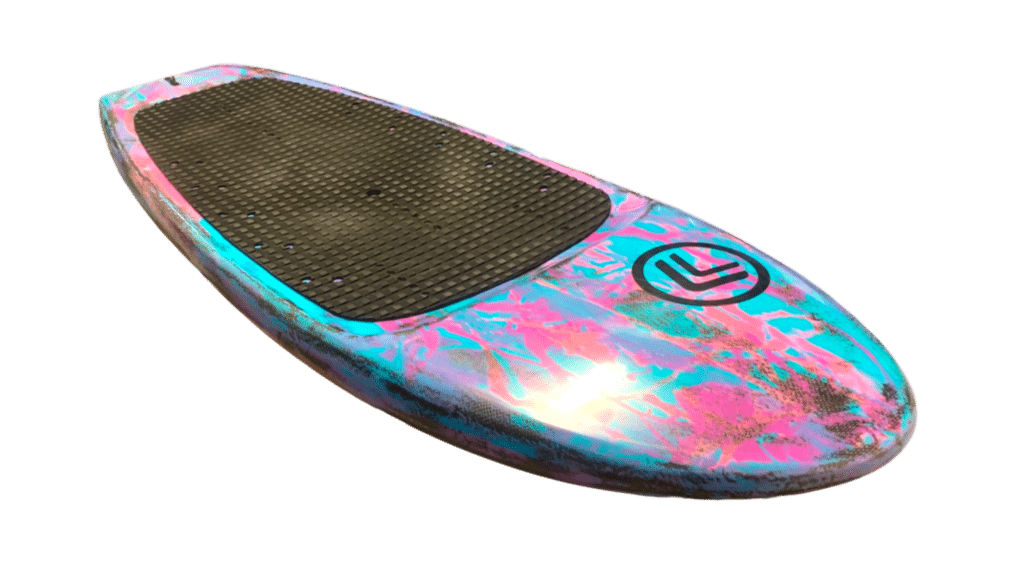

Board shown is FR 73L

3D view

SWIFT // FR

Board shown is FR 73L

The details

SWIFT // Free Ride wing foil board is built to order in 4 proven sizes.

Unlike the mass-producers, we cut each board individually and will customise details and dimensions to suit you.

FR 63L

63 litres

5'4"

20"

4.5kg

1575.00

FR 73L

73 litres

5'6"

21"

4.9kg

1575.00

FR 83L

83 litres

5'8"

22"

5.4kg

1675.00

FR 93L

93 litres

5'10"

23"

5.9kg

1675.00

Built with 100% carbon & epoxy laminate

A key design focus was weight. As such the SWIFT //FR our free ride foil board range is built with 100% carbon fibre and epoxy laminate as standard. We use a vacuum epoxy construction to maximize the fibre to resin ratio further increasing the strength to weight ratio of the laminate.

FR 63L wing foil board in Red colour

Finished in a super hard polished epoxy.

Unlike the big brands, we do not use fillers and paint which can easily chip and scratch. We pigment the epoxy with your chosen colour and finish with a clear epoxy gloss coat. This creates the most durable finish possible.

or customise with your own colour scheme

Choose from a range of single, dual colour and fully custom multi colour styles.

We fit indestructible foil boxes

We have one of the strongest foil boxes on the market. Carbon reinforcement and high density foam inserts tie the top and bottom laminates of the board together, sharing the load between them. This provides you the rider with that ultra rigid and connected feel.

Tell us your foil brand and we will customise the foil box location to suit you. We fit both 10.75″ and 16″ tracks as well as a full carbon deep Tuttle (for the racers out there).

and give you a range of footstrap options

Customers reviews

Tech details

All our Free Ride foil boards are built using an epoxy vacuum construction. Epoxies have superior strength compared to cheaper alternative polyester resins so it was an easy decision for us to make.

Vacuum bagging boards during lamination applies an even pressure over the surface which allows us to achieve a greater fibre density within the resin matrix, resulting in a stronger, lighter board.

Our FR foil boards are laminated with 100% carbon fibre.

Carbon fibre has an excellent strength to weight ratio having a low density, high tensile strength and a high Young’s Modulus (stiffness).

We pigment the epoxy during construction rather than painting our boards. Unlike others, you can clearly see we are not using paint to cover up fillers! This also helps keep the weight down and gives a more durable finish that wont scratch off when you put the wing foil board down on the beach.

Each board is sanded by hand. This makes each board unique and one of a kind.

We then finish with a clear UV stabilised epoxy gloss coat polished to a shine.

All our wing foil boards are designed on specialist computer aided design software. This defines the shape and allows us to understand the hydrodynamics including drag, centre of buoyancy and volume distribution. We can prototype new shapes quickly and adjust the design for the optimum board – we go from a concept to a test board within a week which gives us a fantastic feedback cycle to ensure we develop quickly. Using CNC machining we get great accuracy and repeatability of profiles that you could not get from hand shaping.

We believe we have created one of the strongest foil boxes on the market.

The foil Box is the most highly stressed point on the board and as such required us to design and engineer a solution to handle these loads.

We manufactured multiple inserts to transfer these high loads though the board and further strengthened this area with carbon.

We can install lifting handles on the bottom to make getting to the water that bit easier. It is fitted on the bottom so that the wing can be kept away from the foil when carrying everything to the water.

A ‘Gore’ self venting plug is fitted. This prevents the building of pressure within the board, caused by changes in core temperature or altitude when flying.

Angus comments....

The trend towards high aspect foils has required a change in board design.

The speed at which foils become effective is drastically different when comparing low and high aspect foils.

HA foils will stall if you try to pop up onto the foil to early. Thus the design is focused around creating a board that planes early and has low drag.

Why buy Swift Foiling ?

QUALITY

With the big brands you are paying for cheap materials, freight from China, multiple reseller markups, and delivery miles. With SWIFT you are paying for quality materials - epoxy and carbon, producing solid builds that last. No markups - we sell direct to you.

RAPID INNOVATION

With the big brands it can take up to a year for product innovations to appear on a mainstream board. Swift products are continuously developed and every board is current

DEAL WITH THE DESIGNERS

When you buy direct, you deal with the people that design and build your board. If the wind is up, we are riding and testing every week of the year. We know what works.

See what others on the beach are saying...