Swift // DW our performance Carbon downwind foil board

Get out in all conditions

with your Swift // DW

carbon downwind foil board

SWIFT // DW

downwind foil Board shown DW 90L in white with emerald green swirls

The Swift // DW – Our downwind SUP engineered to make paddling onto foil almost effortless!

Originally crafted to help us fly smaller foils, we quickly realized this shape is ideal for everyone—from beginners taking their first flights to seasoned riders dialing in their smallest foils.

Thoughtful design features ensure easier takeoffs and unmatched control. The added tail rocker enhances foil engagement during takeoff, while the dropped deck brings you closer to the foil for improved responsiveness. Extra volume in the nose and tail provides added stability and a forgiving margin for error when paddling up.

The Swift // DW is your go-to board for smoother, easier, and altogether more enjoyable downwind session.

100% carbon fibre laminate

100% carbon epoxy construction keeps weight to a minimum while providing the strongest stiffest platform.

Shape to suit

What ever your size or ability we are able to build a downwind foil board suit your application.

Hydrodynamic efficiency

Design focused on efficiency, changes to the rocker line and volume distribution drastically reduce the skill and effort required to get up on foil.

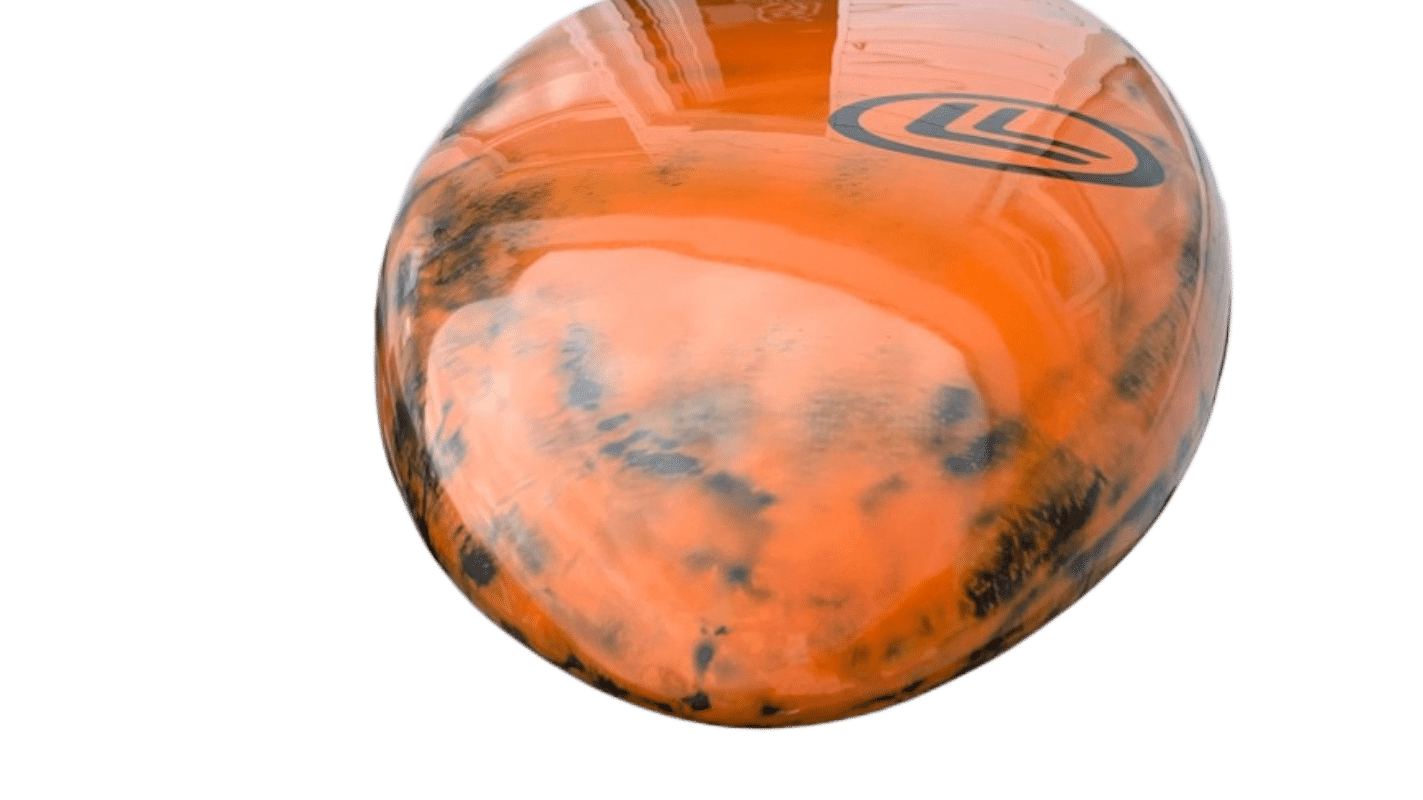

3D view

SWIFT // DW

The Downwind Foil Board shown is DW 7'10" x 16.5" x 97L

The details

SWIFT // DW our downwind foil board is built to order

Unlike the mass-producers, we cut each board individually and will customise details and dimensions to suit you.

Swift // DW

The DW is the high performance board with the design focused on paddle speed. The boards are slightly longer and skinnier than the other equivalent sizes. This comes at a cost to stability making this range better suited to more experienced paddlers.

DW 97L

Volume

97 litres

Size

7'10" x 16.5"

£ 1795

DW 112L

Volume

112 litres

Size

8'0" x 18"

£ 1845

DW Pro 120L

Volume

120litres

Size

8' 0" x 20"

£ 1845

Built with 100% carbon & epoxy laminate

A key design focus was weight. As such the SWIFT //DW our downwind foil board range is built with 100% carbon fibre and epoxy laminate as standard. We use a vacuum epoxy construction to maximize the fibre to resin ratio further increasing the strength to weight ratio of the laminate .

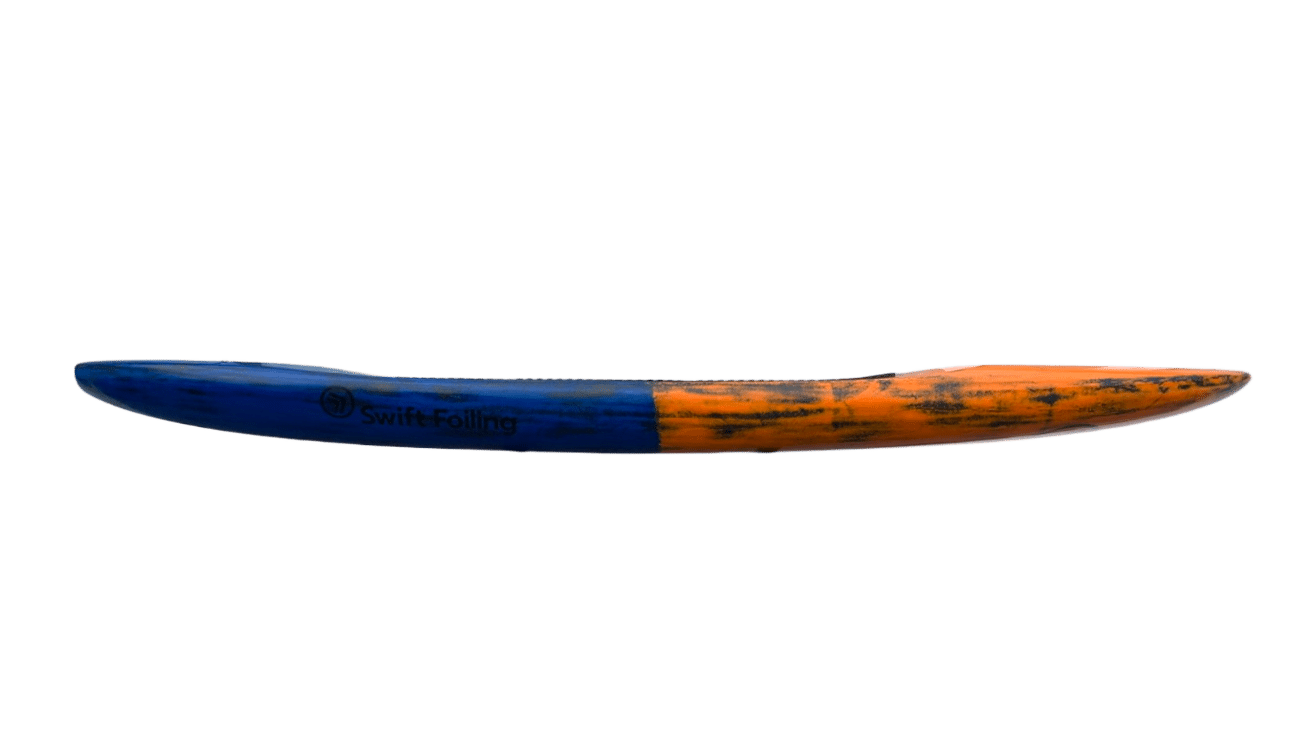

Downwind foil board DW 97L in Red

Finished in a super hard polished epoxy.

Unlike the big brands, we do not use fillers and paint which can easily chip and scratch. We pigment the epoxy with your chosen colour and finish with a clear epoxy gloss coat. This creates the most durable finish possible.

or customise with your own colour scheme

Choose from a range of single, dual colour and fully custom multi colour styles.

Fitted with16" Chinook Tracks as standard

Whatever your riding style or foil selection, 16” tracks gives more than enough adjustability to position your mast exactly where it suits you. With our internal board structure, we have created one of the strongest foil boxes on the market. This provides you, the rider, with that ultra rigid and connected feel.

Tech details

All our downwind foil boards are built using an epoxy vacuum construction. Epoxies have superior strength compared to cheaper alternative polyester resins so it was an easy decision for us to make.

Vacuum bagging boards during lamination applies an even pressure over the surface which allows us to achieve a greater fibre density within the resin matrix, resulting in a stronger, lighter board.

Our downwind foil boards are laminated with 100% carbon fibre.

Carbon fibre has an excellent strength to weight ratio having a low density, high tensile strength and a high Young’s Modulus (stiffness). With prone boards being so thin the stiffness must be provided by the laminate and so 100% carbon construction is necessary to create a strong and rigid yet lightweight board.

We pigment the epoxy during construction rather than painting our boards. Unlike others, you can clearly see we are not using paint to cover up fillers! This also helps keep the weight down and gives a more durable finish that wont scratch off when you put the board down on the beach.

Each board is sanded by hand. This makes each board unique and one of a kind.

We then finish with a clear UV stabilised epoxy gloss coat polished to a shine.

All our downwind foil boards are designed on specialist computer aided design software. This defines the shape and allows us to understand the hydrodynamics including drag, centre of buoyancy and volume distribution. We can prototype new shapes quickly and adjust the design for the optimum board – we go from a concept to a test board within a week which gives us a fantastic feedback cycle to ensure we develop quickly. Using CNC machining we get great accuracy and repeatability of profiles that you could not get from hand shaping.

The foil Box is the most highly stressed point on the board and as such required us to design and engineer a solution to handle these loads.

We manufactured multiple inserts to transfer these high loads though the board and further strengthened this area with carbon.

We are proud to say we have never had a foil box rip out or fail and believe we have created one of the strongest on the market.

A ‘Gore’ self venting plug is fitted. This prevents the building of pressure within the board, caused by changes in core temperature or altitude when flying.

Dom's comments....

Downwind foiling has to be one of the most addictive and rewarding sports out there. However, paddling up onto foil is inherently difficult and so the focus for design has been hydrodynamic efficiency in an effort to make things that bit easier.

Increasing the length to width ratio of boards drastically reduces the amount of effort required to get up on foil. This is seen in the market trending towards the longer narrower downwind foil board.

In addition a subtle rocker profile and a pinned in tail both help to create a downwind foil board which paddles quickly and can catch even the smallest and flattest of swells. As always we have optimized the volume distribution to maximize stability and place the buoyancy exactly where it is needed.

The caveat is that going too narrow creates an unstable board. This won’t allow you to put all your power down when paddling and can be very tricky to stand on in a confused sea state. It’s definitely worth considering what you predominantly want to use the board for and what skill level you have when choosing your board.

Why buy Swift Foiling ?

QUALITY

With the big brands you are paying for cheap materials, freight from China, multiple reseller markups, and delivery miles. With SWIFT you are paying for quality materials - epoxy and carbon, producing solid builds that last. No markups - we sell direct to you.

RAPID INNOVATION

With the big brands it can take up to a year for product innovations to appear on a mainstream board. Swift products are continuously developed and every board is current

DEAL WITH THE DESIGNERS

When you buy direct, you deal with the people that design and build your board. If the wind is up, we are riding and testing every week of the year. We know what works.

See what others on the beach are saying...