How we build the best wing foil boards

When we started this project we wanted to make the best foiling wingboards boards. Light but stiff, easy to sail, with a shape that got up and foiled quickly. Here's how we did it...

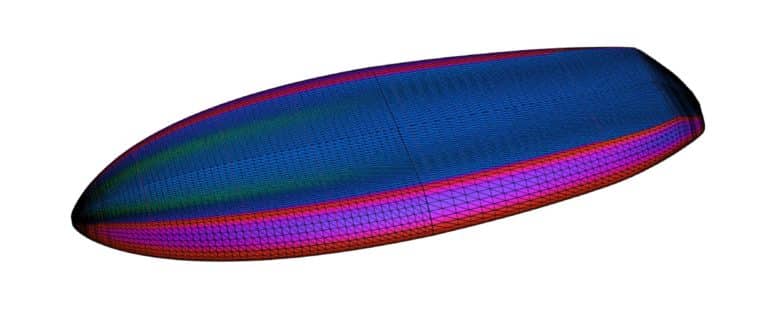

First we optimised the profile

All our boards are designed on specialist computer aided design software. This defines the shape and allows us to understand the hydrodynamics including drag, centre of buoyancy and volume. We build in different volumes to suit ability – as your skills improve you will want a smaller board to reduce weight and windage.

Repeatable shaping with CNC

To make our boards accurately we first designed and made our own purpose built CNC machine.

After refining and calibrating the machine, we are now able to cut with 0.1mm accuracy. We can prototype new shapes quickly and adjust the design for the optimum board – we go from a concept to a test board within a week which gives us a fantastic feedback cycle to ensure we develop quickly. Using CNC we get great machining accuracy and repeatability of profiles that you could not get from hand shaping.

Extra strong foil mount

The foil mount is the most highly stressed point on the board and as such required us to design and engineer a solution to handle these loads.

We manufactured multiple insert to transfers these high loads though the board and further strengthened this with carbon fibre.

At this stage we also fit other HD inserts.

We install lifting handles on the bottom to make getting to the water that bit easier. It is fitted on the bottom so that the wing can be kept away from the foil when carrying everything to the water.

There is also a self venting plug fitted to the deck. This prevents the building of pressure within the board, caused by changes in core temperature or altitude when flying.

Finally a leash plug is inserted at the back.

Light but tough lamination

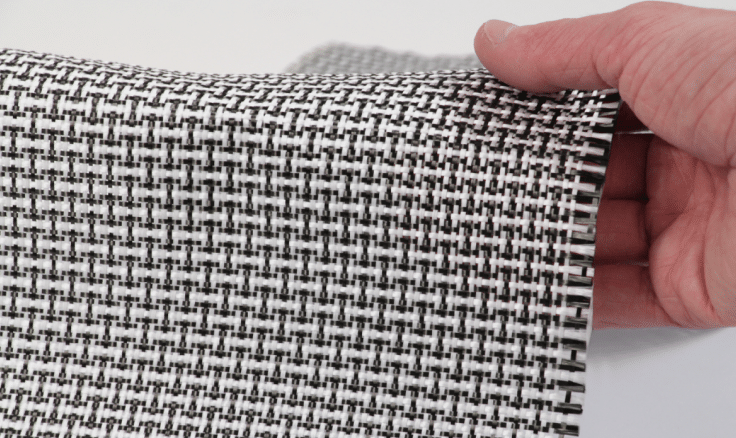

Our wingboards are laminated with a hybrid cloth woven from both Carbon and Innegra fibres.

Carbon fibre has an excellent strength to weight ratio having a low density, high tensile strength and a high Young’s Modulus (stiffness). However, it fails catastrophically due to poor fracture toughness. For this reason full carbon boards are easily damaged and tend to be over built to compensate for this, actually making them heavier.

Innegra is a strong, light weight fibre. Having similar properties to kevlar it is incredibly tough. However, unlike kevlar which wicks water, Innegra is hydrophobic, making it the perfect material for water sports equipment.

By combining Carbon and Innegra in one weave, we get the benefits of both. We have run multiple tests on different layups and chosen the layup with the best balance of strength and weight.

Epoxy vacuum construction

All our boards are built using an epoxy vacuum construction with carbon reinforcement added to high stress areas.

Epoxies have superior strength compared to cheaper alternative polyester resins so it was an easy decision for us to make.

Vacuum bagging boards during lamination applies an even pressure over the surface which allows us to achieve a greater fibre density within the resin matrix, resulting in a stronger, lighter board.

Our final boards have been tested to destruction with various structural impacts and considerably out-perform mass production moulded polyester boards from big name manufacturers.

No paints used

We pigment the epoxy during construction rather than painting our boards. Unlike others, you can clearly see we are not using paint to cover up fillers! This also helps keep the weight down and gives a more durable finish that wont scratch off when you put the board down on the beach.

Each board is sanded by hand. This gives each board a unique and one of a kind finish.

Polished to a shine

Our final finish is a polished clear UV stabilised epoxy coat. We do not paint our boards so there will be no chipping and flaking.

Weighs in lighter

Our standard boards are tough and weigh in at around 6.5 kg for a 100 litre board.