Swift // PR our performance carbon prone foil board

Catch more waves

on a Swift // PR carbon prone foil board...

SWIFT // PR

The SWIFT // PR is our high performance carbon prone foil board for foilers looking to take their riding to the next level. It is available in 4 standard sizes which can be customised to suit you.

Light weight and strong

Our 100% carbon epoxy construction keeps weight to a minimum while providing the strongest stiffest platform.

Easy wave pick up

The PR is designed to paddle quickly and pick up energy to help you catch even the smallest, mushiest UK waves.

Constantly Developing

While sticking with the key features which identify the PR as our performance prone foil board we are constantly developing the design making incremental improvements to stay ahead of the curve.

3D view

SWIFT // PR

Board shown is PR prone foil board 30L

The difference was crazy, so light in comparison and my pump game went through the roof.

HUGO JONES

Custom SWIFT // PR 26L

The details

SWIFT // PR prone foil board is built to order in full show carbon in 4 proven sizes.

Unlike the mass-producers, we cut each board individually and will customise details and dimensions to suit you.

PR 26L

Volume

26 litres

Size

4' 4" x 18.8" x 2.5"

£ 1145

PR 30L

Volume

30 litres

Size

4' 6" x 19.5" x 2.6"

£ 1145

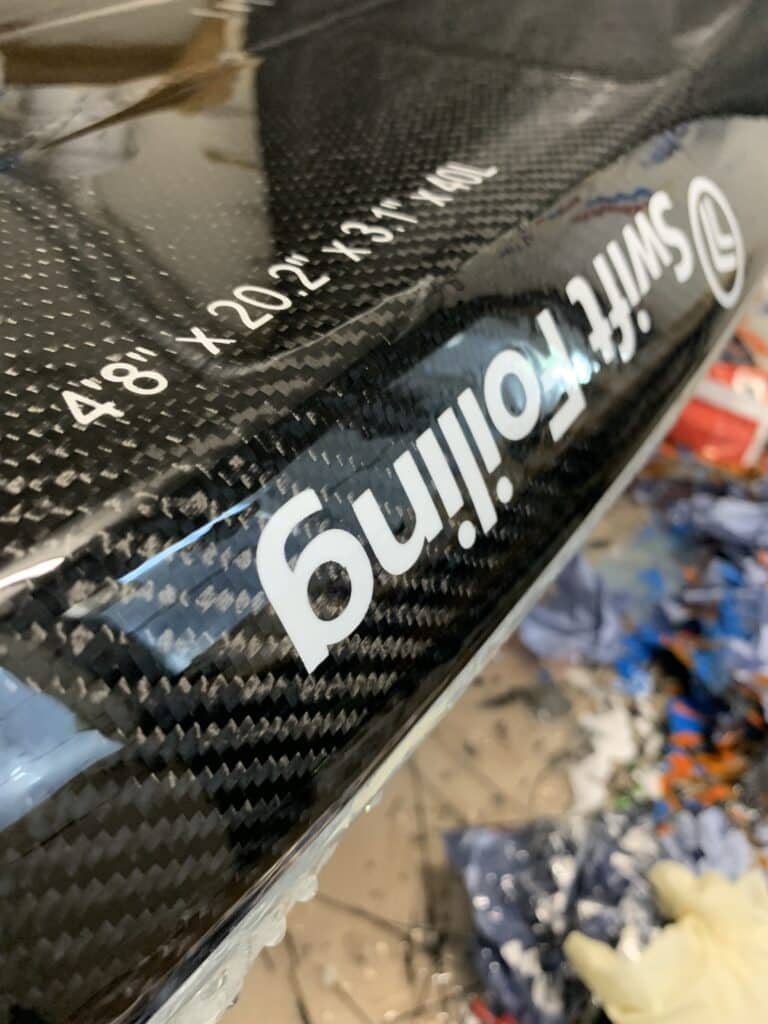

PR 40L

Volume

40 litres

Size

4' 8" x 20.2" x 3.1"

£ 1145

PR 47L

Volume

47 litres

Size

5' 0" x 21" x 3.4"

£ 1145

Built in full show carbon epoxy

The SWIFT // PR prone foil board is built with a premium twill weave carbon cloth and epoxy resin as standard. We use a vacuum construction to increase the fiber density within the matrix. This creates a laminate with a better strength to weight ratio.

Finished in a super hard polished epoxy gloss coat.

Unlike the big brands, we do not use spray lacquers which can easily chip and scratch. We put on a clear epoxy gloss coat. This creates the most durable finish possible.

or talk to us about your own colour overlay

Choose from a range of single, dual colour and fully custom multi colour styles.

With a choice of epoxy pigments and styles we will make your board unique

Boards shown here are NG range but we can do similar things on all our boards including special effects over show carbon

Fitted with16" Chinook Tracks as standard

Whatever your riding style or foil selection, 16” tracks gives more than enough adjustability to position your mast exactly where suits you. With our internal board structure, we have created one of the strongest foil boxes on the market. This provides you, the rider, with that ultra rigid and connected feel.

3mm corduroy Supagrip deckpad as standard or go custom with Surfdek

Our prone foil boards come as standard with our 3mm corduroy tread “Supagrip” deck pad. You can also choose to upgrade this to a customisable “SurfDek” pad. With this upgrade you have the ability to choose tread pattern and colour. This also comes with the added feature of a relay tag in the case your board gets lost.

3M Supagrip deckpad

Tech details

All our boards are built using an epoxy vacuum construction. Epoxies have superior strength compared to cheaper alternative polyester resins so it was an easy decision for us to make.

Vacuum bagging boards during lamination applies an even pressure over the surface which allows us to achieve a greater fibre density within the resin matrix, resulting in a stronger, lighter board.

Our prone foil boards are laminated with 100% carbon fibre.

Carbon fibre has an excellent strength to weight ratio having a low density, high tensile strength and a high Young’s Modulus (stiffness). With prone boards being so thin the stiffness must be provided by the laminate and so 100% carbon construction is necessary to create a strong and rigid yet lightweight board.

Unlike the big brands, we do not use spray lacquers which can easily chip and scratch. We put on a special clear epoxy gloss coat polished to a shine. This creates the most durable finish possible.

All our boards are designed on specialist computer aided design software. This defines the shape and allows us to understand the hydrodynamics including drag, centre of buoyancy and volume distribution. We can prototype new shapes quickly and adjust the design for the optimum board – we go from a concept to a test board within a week which gives us a fantastic feedback cycle to ensure we develop quickly. Using CNC machining we get great accuracy and repeatability of profiles that you could not get from hand shaping.

The foil Box is the most highly stressed point on the board and as such required us to design and engineer a solution to handle these loads.

We manufactured multiple inserts to transfer these high loads though the board and further strengthened this area with carbon.

We are proud to say we have never had a foil box rip out or fail and believe we have created one of the strongest on the market.

A ‘Gore’ self venting plug is fitted. This prevents the building of pressure within the board, caused by changes in core temperature or altitude when flying.

Angus comments....

With our team of dedicated prone foilers we set the brief to create a range of high performance prone foil boards optimised for UK conditions.

The shape places the volume under your chest for ease of paddling and catching waves, whilst the pulled in tail means you don’t catch the rails during turns or when pulling off the wave.

The squash tail enables easy takeoffs on both green waves and white water chip-ins. Hard edges through the tail section give you directional stability when coming off foil and hitting foam. The double concave under your chest releases from the water quickly and helps you bounce back on touchdowns.

Keeping the thickness to a minimum gives you that connected feeling while the full carbon laminate provides all the stiffness required for maximum efficiency when pumping.

The 16” boxes mean you have maximum flexibility for foil placement depending on conditions, foil choice and rider style.

Why buy Swift Foiling ?

QUALITY

With the big brands you are paying for cheap materials, freight from China, multiple reseller markups, and delivery miles. With SWIFT you are paying for quality materials - epoxy and carbon, producing solid builds that last. No markups - we sell direct to you.

RAPID INNOVATION

With the big brands it can take up to a year for product innovations to appear on a mainstream board. Swift products are continuously developed and every board is current

DEAL WITH THE DESIGNERS

When you buy direct, you deal with the people that design and build your board. If the wind is up, we are riding and testing every week of the year. We know what works.

See what others on the beach are saying...